UNDERSTANDING PRINTING PAPER

Choosing the correct paper for your project is an important and sometimes crucial decision in your project planning. It’s best to start thinking about the paper choice from the beginning as it can impact many aspect of the printing process from how ink sits on the paper to how it folds. If you have questions regarding a suitable paper for your project, start by ask your account manager to help you. They can help guide you through the process and can recommend practical and cost effective options.

The first step is to consider how the piece will be used. Some questions you need to ask yourself are:

Does the piece need some rigidity?

The weight or thickness of the paper may be an important consideration.

Will the piece be folded?

You may need to think about the grain of the paper and if the paper will need to be scored to be folded without cracking.

Will you need to be able to write on the paper?

If so you will need to think about the coating of the stock.

Are you printing a booklet?

You will need to choose both text and cover stocks if you want the book pages lighter than the cover.

Are you limited to certain types of paper for digital printing?

Ink and paper technologies are constantly changing. Today there are many papers to choose from for digital printing. Ask your account manager for more details.

Are you looking for more uniqueness?

There are many specialty stocks with various textures which can enhance a project.

Understanding the characteristics of paper will help you better select the appropriate stock for your project. There are three main categories that are particularly important: Weight /Thickness/Grain, Coatings, and Finishes.

WEIGHT / THICKNESS /GRAIN

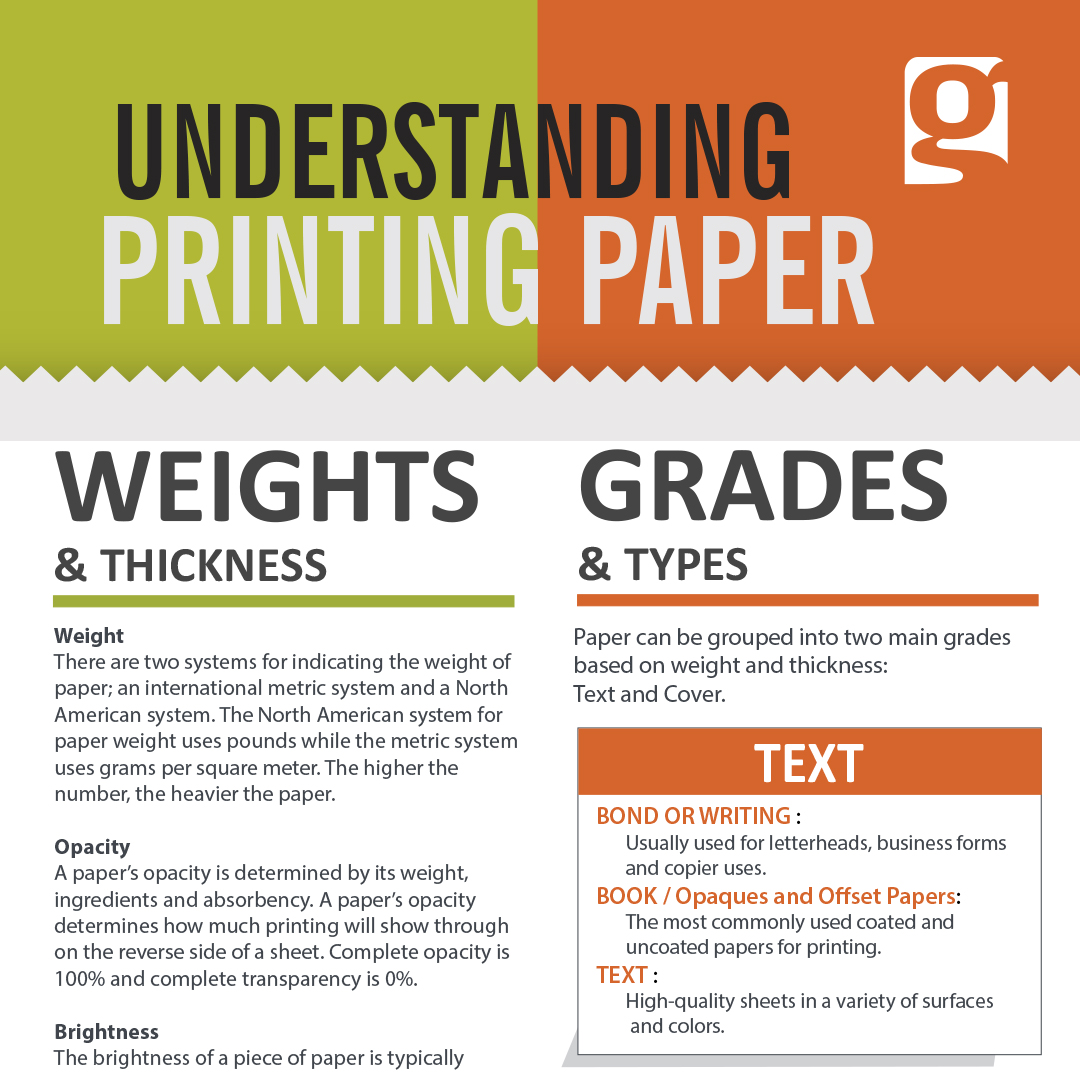

Paper weight can be somewhat confusing, particularly because there are two systems of indicating the weight of paper. The metric system is used internationally and is pretty straight forward; it measures the weight of a square meter of paper and represents the weight in grams per square meter (GSM).

In the US however, weight is measured in pounds (#). 500 sheets of paper (or 1 ream) at the basis size (basis size differs depending on grade of paper) are weighed to yield the weight in pounds. The fact that different grades of paper each have different a basis size, makes for a difficult calculation.

The three most common weights of bond are 20 lb., 24 lb., and 28 lb., which correlate exactly to offset (uncoated text) weights of 50 lb., 60 lb., and 70 lb., respectively (i.e. 20 lb. bond = 50 lb. offset). For cover stocks, 60 lb, 65 lb, 80 lb. and 100 lb. tend to be the most common weights. The higher the weight of the paper, the thicker it is. The caliper (or thickness) of paper is expressed in thousandths of an inch.

Case Paper provides a Paper Thickness Chart that can be downloaded here.

Opacity

A paper’s opacity is determined by its weight, ingredients and absorbency. A paper’s opacity determines how much printing will show through on the reverse side of a sheet. Complete opacity is 100% and complete transparency is 0%.

Brightness

The brightness of a piece of paper is typically expressed on a scale of 1 to 100 with 100 being the brightest. The brightness of a paper affects readability, the perception of ink color and the contrast between light and dark hues.

Grain

A paper's grain is the direction in which most of the fibers lie. Paper is identified as either grain short (grain is parallel to paper's short side) or grain long (grain is parallel to the paper's long side), depending on how the paper is cut.

It is best to fold paper parallel to the grain direction. Paper folded against the grain may be rough and crack along the folded edge. The heavier the paper, the more likely roughness and cracking will occur. We suggest you score heavier papers prior to folding. (*Score: To compress paper along a straight line so it folds better. Also called a crease.)

GRADES OR TYPE OF PAPER

Paper can be grouped into two main types based on weight and thickness: Text and Cover.

Text and Cover papers are offered in a wide variety of colors from lights to darks, with numerous textures and a variety of surface finishes.

The difference between text and cover papers is primarily one of weight. Text papers are typically used for the inside pages of books, brochures, annual reports and direct mail pieces. The weight of Text papers also lends itself to advertising flyers as well as letterhead and communication systems. Papers in the category can be further broken out into: Bond or Writing (copier, letterheads, forms); Book or Offset (both coated and uncoated); Text (high-quality sheets in a variety of textures and colors).

Cover papers are heavier than Text sheets and are generally used for the covers of brochures, annual reports and folders where extra bulk is needed. They can come coated or uncoated or in a variety of colors and textures.

FINISHES

Finally, paper can be separated by whether it is coated or uncoated.

Coated paper has a surface sealant that changes the absorbency and finish of the paper—much like varnish on wood. When a paper is coated it absorbs less moisture and printing inks sit on the surface, rather than ‘sinking in’. As a result a coated paper can give a more clear, defined and glossy result for your printing. Coated paper is also more resistant to dirt, moisture and wear and makes the printed material shinier. That is why it is generally used in the printing of magazines, book covers, glossy photos and art books. Coated papers however, are not good if you need to write on the piece and would not be desirable for things like forms. Coated sheets also have limited range of colors and finishes

Coated paper can be further categorized by type of coating:

GLOSS

gloss coated paper has a high sheen and perfect for excellent color definition

SILK

has a lower gloss level, but colors are still sharp and vivid

DULL

a dull finish coated paper has a smooth surface and is low in gloss

MATTE

a matte coated paper is a non-glossy, flat looking paper with very little sheen.

Uncoated papers have a more natural feel to them and also offer a greater variety of options for your print project, including more colors, visual effects and surface textures. They can also suggest a high-end feel just as well as coated paper can. Uncoated papers are more porous however and can cause colors to look dull and the ink is absorbed into them.

Uncoated papers also come in different textures:

Smooth

Both coated and uncoated paper can have a smooth finish.

Linen

Has a rich texture and feel of natural linen

Laid

A type of paper having a ribbed texture

Again, always start by defining the nature of your project and then ask your account manager to help you make the right choice!

We have provided an infographic that reviews everything you need to know about choosing the right paper. Click here to download the full infographic.